Intelligent Multifunctional Fiber Laser Cutting Machine

Model | LT-F1530 | LT-F1560 | LT-F2040 | LT-F2060 |

| Working Area | 150*300cm | 150*600cm | 200*400cm | 020*600cm |

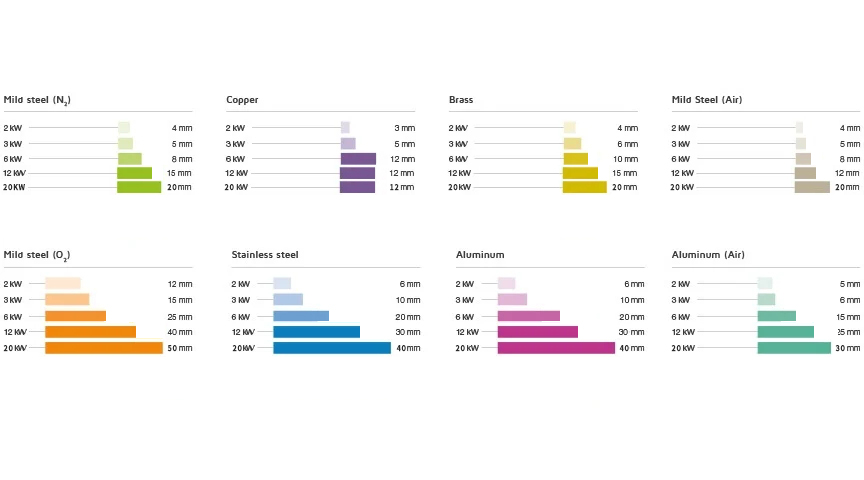

Laser Power | 1000w-20000w | 1000w-20000w | 1000w-20000w | 1000w-20000w |

Positioning Accuracy | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

Repeat Repositioning Accuracy | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm |

Max Movement Speed | ±0.02mm | ±0.02mm | ±0.02mm | 200m/min |

Max Acceleration | 1.5G | 1.5G | 1.5G | 380V |

| Working Voltage | 380V | 380V | 380V | cs |

Maximun Load | 2000kg | 4000kg | 3000kg | 6000kg |

Machine Weight | 3000kg | 5000kg | 4000kg | 7000kg |

Operating Humidity | <90% | <90% | <90% | <90% |

Operating Temperature | 0℃-40℃ | 0℃-40℃ | 0℃-40℃ | 0℃-40℃ |