In the ever-evolving manufacturing sector, precision, speed, and reliability are critical components for success. One of the challenges faced by businesses involved in pipe processing is the need for accurate and efficient cutting solutions that can handle a variety of materials and pipe sizes. This is where a semi-automatic feeding pipe cutting machine can make a significant difference, offering enhanced productivity and reducing human error in pipe cutting operations.

A semi-automatic feeding pipe cutting machine is designed to streamline the process of cutting pipes with minimal manual intervention. Unlike fully manual or automatic systems, semi-automatic machines offer a balance of user control and automation, providing flexibility for a wide range of pipe cutting applications. These machines are equipped with feeding mechanisms that automatically feed pipes into the cutting area, allowing operators to focus on controlling the machine’s other aspects, such as the cutting speed and depth.

Precision and Accuracy: One of the most notable advantages of using a semi-automatic feeding pipe cutting machine is its ability to achieve highly accurate and consistent cuts. These machines are designed with advanced control systems that ensure each cut is precise, minimizing the chances of errors that can result in waste or the need for rework.

Increased Efficiency: With the semi-automatic feeding system, pipes are fed into the cutting area automatically, reducing the time spent on manual handling and setup. This helps increase throughput and reduce downtime, especially for businesses that handle high volumes of pipes. The operator can adjust settings to suit different pipe diameters, material types, and cutting needs.

Versatility: These machines can handle a variety of materials such as steel, aluminum, copper, and other metals commonly used in industries like construction, plumbing, and HVAC. Whether it's thin-walled pipes or heavy-duty industrial tubing, a semi-automatic feeding pipe cutting machine is equipped to manage diverse cutting tasks with ease.

Cost-Effectiveness: While fully automatic machines can be costly, semi-automatic machines offer a more budget-friendly solution without sacrificing quality. By combining automation with manual oversight, businesses can achieve high-quality results at a lower investment compared to fully automated systems.

User-Friendly Operation: Even though these machines offer automation, they remain highly accessible to operators. The user interface is typically designed to be intuitive, allowing operators to quickly learn and operate the system with minimal training. This ease of use helps reduce the learning curve and increase overall operational efficiency.

Reduced Material Waste: The precise nature of semi-automatic cutting machines means that there is less material wastage compared to manual methods. This not only helps businesses save on material costs but also contributes to more sustainable manufacturing practices.

These machines are widely used in a variety of industries where accurate pipe cutting is essential. For instance, in the construction and plumbing industries, precise cuts are needed for installing piping systems. Similarly, in HVAC, the precise cutting of pipes ensures that systems function efficiently without leaks. Other industries, such as automotive manufacturing and oil and gas, also benefit from the versatility and efficiency offered by semi-automatic feeding pipe cutting machines.

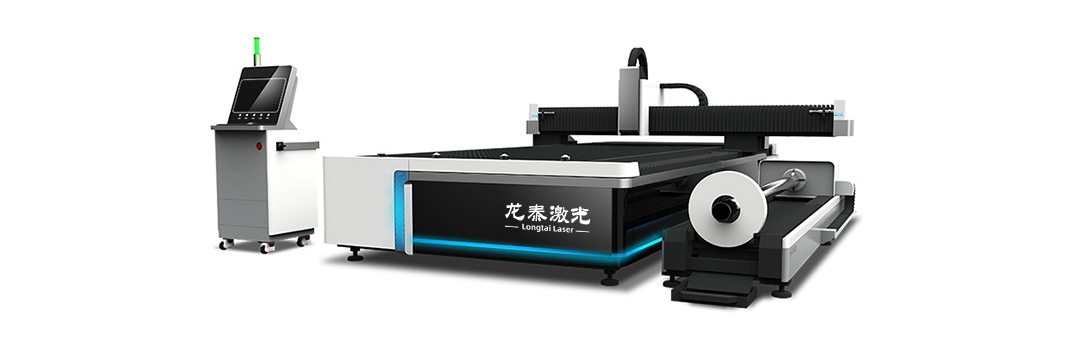

At Longtai Laser, we understand the importance of reliable and efficient pipe cutting equipment. Our semi-automatic feeding pipe cutting machines are engineered with cutting-edge technology to deliver precision, performance, and versatility. With a focus on quality and customer satisfaction, we provide solutions that enhance your production capabilities while ensuring ease of use and longevity.

Whether you're processing small batches of pipes or large-scale production runs, our machines are built to handle your needs with efficiency and cost-effectiveness. Explore our product offerings and see how we can help streamline your operations with advanced cutting solutions.