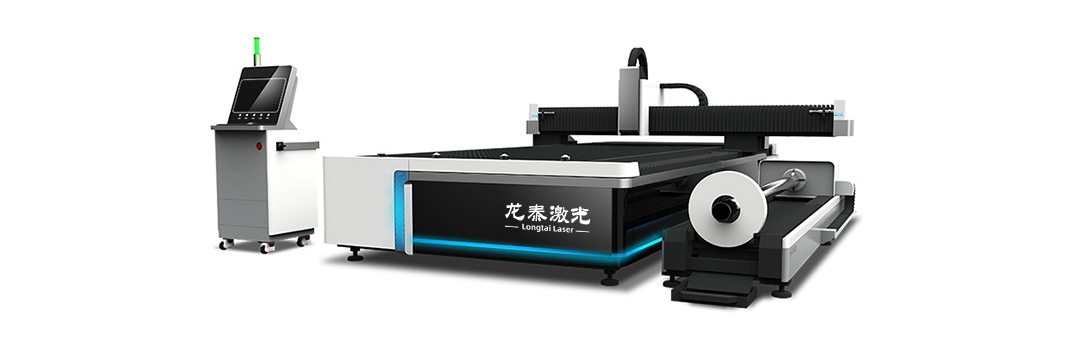

In today’s fast-paced manufacturing landscape, the demand for efficient, precise, and versatile cutting solutions continues to grow. From metal fabrication to automotive parts production, and from electronics manufacturing to aerospace component processing, businesses are constantly seeking tools that can keep up with evolving production needs while maintaining high standards of quality. This is where the cutting fiber laser machine stands out as a game-changer—and Longtai Laser has been at the forefront of delivering advanced fiber laser cutting solutions tailored to these diverse industry requirements.

Why Cutting Fiber Laser Machines Are Redefining Industrial Cutting

Traditional cutting methods, such as plasma cutting or mechanical sawing, often come with limitations: slower processing speeds, inconsistent precision, higher material waste, and difficulty handling thin or complex materials. Cutting fiber laser machines address these challenges head-on, leveraging the unique properties of fiber laser technology to deliver results that meet the demands of modern manufacturing.One of the key advantages of a cutting fiber laser machine is its exceptional precision. Fiber lasers produce a narrow, high-intensity beam that can make intricate cuts with minimal heat-affected zones (HAZ). This means cleaner edges, reduced material distortion, and less post-processing work—critical for industries like electronics, where even tiny deviations can compromise product performance.Efficiency is another standout feature. Compared to traditional cutting tools, fiber laser cutting machines operate at significantly faster speeds, especially when working with non-ferrous metals (such as aluminum and copper) and thin to medium-thickness steel. This speed boost translates to higher production throughput, allowing businesses to take on more orders and shorten lead times without sacrificing quality.Additionally, cutting fiber laser machines offer versatility that few other cutting technologies can match. They can handle a wide range of materials—including stainless steel, carbon steel, brass, titanium, and even some non-metallic materials like acrylic and wood—making them a one-stop solution for businesses with diverse cutting needs. Whether you’re producing small, detailed components or large, structural parts, a fiber laser cutting machine can adapt to the task.Energy efficiency is also a notable benefit. Fiber laser systems consume less power than CO2 laser machines (a common alternative) while delivering comparable or better cutting performance. This not only reduces operational costs for businesses but also aligns with global efforts to minimize industrial carbon footprints—a priority for many modern manufacturers.

Longtai Laser: Engineering Cutting Fiber Laser Machines for Reliability and Performance

For over a decade, Longtai Laser has focused on designing and manufacturing industrial-grade cutting fiber laser machines that combine durability, precision, and user-friendliness. Our team of engineers and technical experts works closely with clients across industries to understand their unique cutting challenges, ensuring that each machine we produce is optimized to meet their specific needs.

Key Features of Longtai Laser’s Cutting Fiber Laser Machines

- High-Quality Laser Sources: We partner with leading global laser source manufacturers to integrate reliable, high-power lasers into our machines. Whether you need a 1kW machine for thin material cutting or a 12kW machine for thick steel processing, our systems are equipped to deliver consistent performance day after day.

- Robust Mechanical Structure: Longtai’s cutting fiber laser machines feature a heavy-duty frame constructed from high-quality steel, designed to minimize vibration during operation. This stability is critical for maintaining precision, even during long production runs, and ensures the machine’s longevity—an important investment for any manufacturing business.

- Advanced Control Systems: Our machines are equipped with intuitive, industry-leading control software that simplifies operation while offering advanced features for complex cutting tasks. The software supports multiple file formats (including DXF, AI, and PLT) and allows for real-time adjustment of cutting parameters, making it easy for operators to optimize performance for different materials and thicknesses.

- Automatic Material Handling Options: To further enhance efficiency, we offer optional automatic loading and unloading systems for our cutting fiber laser machines. These systems reduce manual labor, minimize material handling time, and allow for 24/7 unattended operation—ideal for businesses looking to maximize productivity.

- Comprehensive Safety Features: Safety is a top priority at Longtai Laser. Our cutting fiber laser machines include safety enclosures, emergency stop buttons, and laser safety interlocks to protect operators and comply with global safety standards. We also provide detailed safety training to ensure that every user can operate the machine with confidence.

Applications: Where Longtai’s Cutting Fiber Laser Machines Excel

Longtai’s cutting fiber laser machines are trusted by businesses in a wide range of industries, thanks to their versatility and performance. Some of the most common applications include:

- Metal Fabrication: Cutting precise shapes and holes in stainless steel, carbon steel, and aluminum for products like metal furniture, storage racks, and decorative components.

- Automotive Manufacturing: Producing lightweight, high-precision parts such as chassis components, engine parts, and interior trim pieces.

- Aerospace and Defense: Cutting complex, thin-walled components from high-strength materials like titanium and Inconel, where precision and material integrity are non-negotiable.

- Electronics: Creating small, detailed cuts in copper and aluminum for circuit boards, heat sinks, and electronic enclosures.

- Medical Device Manufacturing: Cutting biocompatible materials like stainless steel and titanium for surgical instruments, implants, and medical equipment parts.

Why Choose Longtai Laser for Your Cutting Fiber Laser Machine Needs?

Investing in a cutting fiber laser machine is a significant decision, and choosing the right manufacturer is key to ensuring that your investment delivers long-term value. Here’s why businesses around the world trust Longtai Laser:

- Customization: We don’t offer “one-size-fits-all” solutions. Instead, we work with you to customize your cutting fiber laser machine—from laser power and bed size to additional features like automatic material handling—to match your exact production requirements.

- Global Support: Longtai Laser has a network of service centers and technical support teams across Asia, Europe, North America, and Africa. Whether you need installation assistance, maintenance services, or troubleshooting help, our team is available to support you quickly and efficiently.

- Proven Track Record: Over the years, we have delivered thousands of cutting fiber laser machines to clients in more than 50 countries. Our machines are known for their reliability, and we have built long-term partnerships with businesses of all sizes—from small workshops to large multinational manufacturers.

- Continuous Innovation: The field of fiber laser technology is constantly evolving, and Longtai Laser is committed to staying ahead of the curve. Our R&D team regularly updates our machine designs and software to incorporate the latest advancements, ensuring that our clients always have access to state-of-the-art cutting solutions.

Get Started with Longtai Laser’s Cutting Fiber Laser Machines

If you’re ready to upgrade your cutting process with a high-performance, reliable cutting fiber laser machine, Longtai Laser is here to help. Whether you’re new to fiber laser cutting or looking to replace an existing system, our team can provide a detailed consultation to help you choose the right machine for your needs.Contact us today to learn more about our cutting fiber laser machines, request a quote, or schedule a demonstration. Let Longtai Laser be your partner in transforming your manufacturing efficiency and precision.