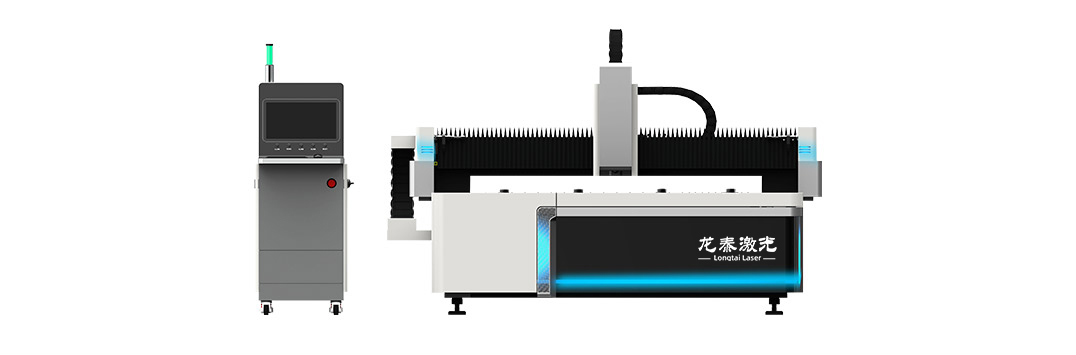

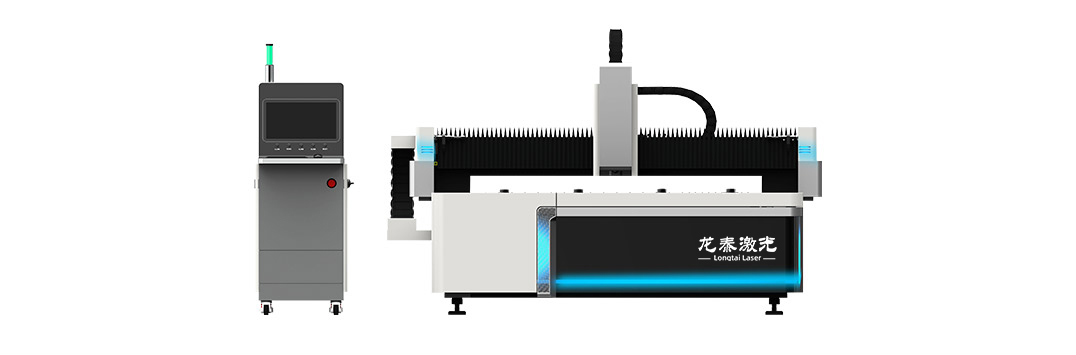

In the dynamic realm of metal processing, the Fiber Laser Cutting Machine has emerged as a game - changing technology, and Longtai Laser is at the forefront of providing high - quality, innovative fiber laser cutting solutions.

Unparalleled Precision and Accuracy

One of the most remarkable features of the fiber laser cutting machine is its ability to achieve extremely high precision. The laser beam, delivered through fiber optics, can be focused to a minuscule spot, allowing for cuts with incredible accuracy. This precision is crucial when working on complex shapes, fine details, or when tight tolerances are required. For example, in the manufacturing of intricate metal components for the electronics industry or delicate parts for the medical device sector, Longtai Laser's fiber laser cutting machines can produce cuts with a precision that is hard to match. The advanced optical system and precise motion control ensure that each cut is clean, sharp, and exactly as designed.

High - Speed Cutting for Enhanced Productivity

Time is money in the manufacturing world, and fiber laser cutting machines offer significant speed advantages. They can cut through a variety of metals at high speeds, reducing production time substantially. The high - power fiber lasers used in Longtai Laser's machines enable rapid material removal. For instance, when cutting thin - gauge stainless steel or aluminum sheets, the cutting speed can reach up to [X] meters per minute. This high - speed cutting not only increases the overall productivity but also makes it possible to meet tight production schedules. In addition, the quick start - up and shutdown times of fiber laser systems mean that there is minimal idle time, further optimizing the production process.

Exceptional Cutting Quality

The quality of the cut is a top priority, and fiber laser cutting machines excel in this aspect. The narrow kerf width produced by the fiber laser results in less material wastage. The heat - affected zone (HAZ) is also significantly smaller compared to other cutting methods. This means that the integrity of the surrounding material is better preserved, reducing the likelihood of warping or other heat - related defects. Longtai Laser's fiber laser cutting machines produce clean, burr - free edges, which often eliminate the need for extensive post - processing. Whether it's for creating smooth - finished parts for the automotive industry or aesthetically pleasing products for the jewelry or decorative metalwork sectors, the high - quality cuts ensure that the final product meets the highest standards.

Versatility in Material Processing

Fiber laser cutting machines are highly versatile and can handle a wide range of materials. They are particularly well - suited for cutting metals such as stainless steel, carbon steel, aluminum, brass, and copper. However, they can also be used to cut certain non - metal materials with appropriate adjustments. Longtai Laser's machines are designed to adapt to different material thicknesses, from thin foils to relatively thick plates. This versatility makes them an ideal choice for various industries, including aerospace, where different metal alloys need to be precisely cut for aircraft components; the construction industry, for cutting metal profiles for building structures; and the signage industry, for creating customized metal signs and letters.

Cost - Efficiency in the Long Run

Although the initial investment in a fiber laser cutting machine may seem substantial, it offers long - term cost - efficiency. The high energy - conversion efficiency of fiber lasers means that they consume less power compared to other laser cutting technologies, such as CO₂ lasers. Additionally, fiber lasers have a longer lifespan and require less maintenance. The absence of complex optical components that are prone to wear and tear, as in traditional laser systems, reduces the need for frequent part replacements. Longtai Laser's fiber laser cutting machines are engineered with reliability in mind, minimizing downtime and associated costs. Over time, these cost - saving factors add up, making fiber laser cutting a cost - effective solution for metal processing operations.

Advanced Technology and Innovation by Longtai Laser

Longtai Laser is committed to continuous innovation in fiber laser cutting technology. Our machines are equipped with state - of - the - art features, such as intelligent control systems that optimize the cutting process based on the material type, thickness, and desired cut quality. The user - friendly interface allows operators to easily program and monitor the cutting process, ensuring smooth operation. We also offer customization options to meet the specific needs of different customers. Whether it's integrating additional features for a particular industry application or tailoring the machine's size and configuration to fit a specific workspace, Longtai Laser has the expertise to deliver customized fiber laser cutting solutions.

In conclusion, the Fiber Laser Cutting Machine, especially those offered by Longtai Laser, represents a significant leap forward in metal processing technology. With its precision, speed, quality, versatility, and cost - efficiency, it has become an indispensable tool for modern manufacturing industries. If you're looking to enhance your metal processing capabilities, consider investing in a Longtai Laser fiber laser cutting machine and experience the difference it can make in your production process.