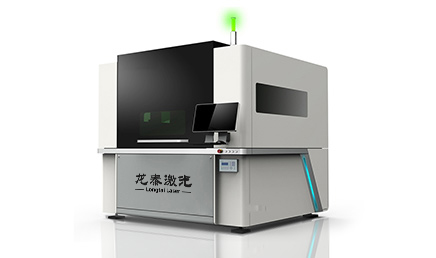

In the ever - evolving landscape of manufacturing and fabrication, the Enclosed Fiber Cutting Machine has emerged as a game - changing technology. Longtai Laser, a renowned name in the laser equipment industry, offers state - of - the - art enclosed fiber cutting machines that are setting new standards for precision, efficiency, and safety.

Understanding the Basics of Enclosed Fiber Cutting Machines

How It Works

At its core, an enclosed fiber cutting machine utilizes a high - power fiber laser source. The laser beam, generated by the fiber laser, is guided through a fiber optic cable to the cutting head. When the beam reaches the material to be cut, it rapidly heats and vaporizes the material, creating a clean and precise cut. The enclosed design of the machine is crucial as it contains the laser beam, protecting operators from potential laser exposure and also minimizing the escape of fumes and debris generated during the cutting process.

Key Components

Fiber Laser Source: Longtai Laser's enclosed fiber cutting machines are equipped with advanced fiber laser sources that deliver high - power and stable laser beams. These sources are known for their energy - efficiency, long lifespan, and ability to produce high - quality cuts on a variety of materials.

Cutting Head: The cutting head is a precision - engineered component that focuses the laser beam onto the workpiece. Longtai Laser's cutting heads are designed to provide accurate beam delivery, allowing for cuts with tight tolerances. They also feature adjustable focusing capabilities, enabling operators to optimize the cutting process for different material thicknesses and types.

Enclosed Work Area: The enclosed work area is not only a safety feature but also contributes to the overall performance of the machine. It is designed to be air - tight, which helps in controlling the flow of assist gases (such as oxygen or nitrogen) used in the cutting process. This controlled environment ensures consistent cut quality and reduces the risk of contamination.

Advantages of Longtai Laser's Enclosed Fiber Cutting Machines

Precision Cutting

One of the standout features of Longtai Laser's enclosed fiber cutting machines is their ability to achieve extremely high precision. With the advanced control systems and high - quality optical components, these machines can produce cuts with tolerances as low as ±0.05mm. This level of precision makes them ideal for applications where intricate designs and tight tolerances are required, such as in the electronics, jewelry, and medical device industries.

High - Speed Cutting

In addition to precision, speed is another area where Longtai Laser's machines excel. The high - power fiber lasers enable rapid cutting speeds, significantly reducing production time. For example, when cutting thin - gauge stainless steel, the machine can achieve cutting speeds of up to several meters per minute. This high - speed cutting not only increases productivity but also helps in reducing overall production costs.

Versatility in Material Processing

Longtai Laser's enclosed fiber cutting machines are capable of cutting a wide range of materials. From metals such as stainless steel, carbon steel, aluminum, and copper to non - metals like acrylic, wood, and plastic, these machines offer unparalleled versatility. The ability to switch between different materials with ease makes them a valuable asset in a variety of manufacturing and fabrication settings.

Enhanced Safety Features

The enclosed design of the machine is a major safety advantage. It completely encloses the laser beam, preventing any accidental exposure to operators. Additionally, the machine is equipped with safety interlocks that automatically shut down the laser if the enclosure door is opened during operation. The enclosed work area also helps in containing fumes and debris, creating a cleaner and safer working environment.

Low Maintenance Requirements

Longtai Laser's enclosed fiber cutting machines are designed for reliability and low maintenance. The fiber laser sources have a long lifespan and require minimal maintenance compared to traditional laser sources. The enclosed design also protects the internal components from dust and debris, reducing the risk of component failure and further minimizing maintenance needs.

Applications of Enclosed Fiber Cutting Machines

Manufacturing Industry

In the manufacturing industry, enclosed fiber cutting machines are used for a wide range of applications. They are used to cut parts for automotive components, such as engine parts, chassis components, and body panels. In the aerospace industry, these machines are used to cut complex parts for aircraft engines, wings, and fuselages. The high precision and speed of the machines make them suitable for mass production as well as for prototyping.

Fabrication Shops

Fabrication shops rely on enclosed fiber cutting machines to cut and shape materials for various projects. Whether it's creating custom - made metal furniture, decorative metalwork, or structural components for buildings, these machines provide the flexibility and precision required. The ability to work with different materials also allows fabrication shops to offer a wide range of services to their customers.

Sign and Display Industry

The sign and display industry benefits greatly from the capabilities of enclosed fiber cutting machines. These machines can cut intricate shapes and designs in materials such as acrylic, aluminum, and stainless steel, which are commonly used in the production of signs, display stands, and decorative elements. The high - quality cuts ensure that the final products have a professional and polished look.

Jewelry Making

In the jewelry making industry, precision is of utmost importance. Longtai Laser's enclosed fiber cutting machines can be used to cut delicate metal components for jewelry, such as chains, pendants, and rings. The ability to create intricate designs with high precision allows jewelry designers to bring their creative visions to life.

Choosing the Right Enclosed Fiber Cutting Machine

When considering an enclosed fiber cutting machine, several factors need to be taken into account.

Cutting Power

The cutting power of the machine determines the thickness and type of materials it can cut. Longtai Laser offers a range of machines with different cutting powers, allowing customers to choose the one that best suits their needs. For cutting thick metals, a higher - power machine is required, while for thinner materials or non - metals, a lower - power machine may be sufficient.

Table Size

The size of the worktable on the machine is another important consideration. It should be large enough to accommodate the size of the materials you typically work with. Longtai Laser offers machines with various table sizes, from small benchtop models for hobbyists and small - scale businesses to large - format machines for industrial applications.

Control System

The control system of the machine plays a crucial role in its ease of use and performance. Longtai Laser's machines are equipped with user - friendly control systems that allow operators to easily program and control the cutting process. The control systems also offer features such as real - time monitoring, which helps in ensuring the quality of the cuts.

In conclusion, Longtai Laser's Enclosed Fiber Cutting Machines offer a combination of precision, speed, versatility, and safety that is hard to match. Whether you are in the manufacturing, fabrication, sign and display, or jewelry making industry, these machines can revolutionize your cutting processes and help you achieve higher productivity and better - quality results. Explore the range of enclosed fiber cutting machines offered by Longtai Laser today and take your business to the next level.