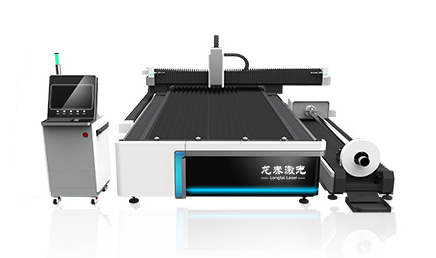

In today’s competitive manufacturing landscape, businesses demand tools that combine precision, efficiency, and versatility. The Sheet & Tube Laser Cutting Machine has emerged as a cornerstone technology for industries ranging from automotive and aerospace to construction and furniture design. At Longtai Laser, we specialize in delivering cutting-edge laser solutions tailored to meet the evolving needs of global manufacturers.

Why Choose a Sheet & Tube Laser Cutting Machine?

Traditional cutting methods often struggle with complex geometries, thick materials, or mixed workloads involving both flat sheets and tubular profiles. A sheet & tube laser cutting machine addresses these challenges by integrating dual functionalities into a single system, enabling seamless transitions between cutting flat materials and tubular structures. This versatility reduces setup times, minimizes material waste, and enhances production flexibility—key advantages for businesses aiming to optimize workflows without compromising quality.

Key Features of Longtai Laser’s Sheet & Tube Solutions

High Precision and Speed

Our machines utilize advanced fiber laser technology to achieve micron-level accuracy, ensuring clean cuts even on intricate designs. With cutting speeds up to 120 m/min (depending on material and thickness), manufacturers can meet tight deadlines without sacrificing detail.

Dual-Function Capability

Designed for multi-tasking environments, Longtai Laser’s systems effortlessly switch between sheet and tube processing. This eliminates the need for separate machines, saving floor space and reducing operational costs.

Material Versatility

From mild steel and stainless steel to aluminum, brass, and even reflective metals, our machines handle a wide range of materials with consistent results. This adaptability makes them ideal for prototyping, small-batch production, and large-scale industrial projects.

User-Friendly Software Integration

Equipped with intuitive nesting software, our systems optimize material usage by automatically arranging parts to minimize scrap. Real-time monitoring and remote diagnostics further simplify operation and maintenance.

Durability and Low Maintenance

Built with robust components and a sealed laser source, Longtai Laser’s machines are engineered for long-term reliability. Reduced downtime and lower energy consumption translate to higher ROI for businesses of all sizes.

Applications Across Industries

The sheet & tube laser cutting machine is a game-changer for sectors requiring precision and efficiency:

Automotive: Fabricate exhaust systems, chassis components, and custom brackets.

Architecture: Create decorative metalwork, railings, and structural elements.

Furniture: Produce intricate frames, legs, and ornamental pieces with smooth edges.

Energy: Manufacture components for solar panels, wind turbines, and piping systems.

Why Longtai Laser Stands Out

At Longtai Laser, innovation is at the heart of everything we do. With over a decade of experience in laser technology, we prioritize:

Customization: Tailor machines to your specific production requirements.

Global Support: Access 24/7 technical assistance and spare parts delivery.

Sustainability: Design energy-efficient systems that align with eco-conscious manufacturing practices.

Ready to Elevate Your Production Capabilities?

Explore Longtai Laser’s range of sheet & tube laser cutting machines and discover how precision engineering can transform your workflow. Visit our website to browse technical specifications, case studies, and client testimonials. For personalized guidance, contact our team of experts today—we’re here to help you stay ahead in a fast-paced industry.

Longtai Laser: Where Precision Meets Possibility.