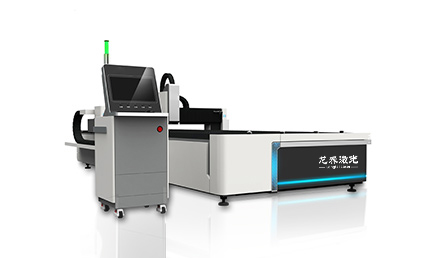

In the ever - evolving world of manufacturing and metalworking, the Sheet Metal Laser Cutting Machine has emerged as a game - changing technology. Longtai Laser, a renowned name in the laser equipment industry, has been at the forefront of providing high - quality sheet metal laser cutting solutions that meet the diverse needs of various sectors.

Sheet metal laser cutting machines utilize high - powered laser beams to cut through different types of sheet metals with extreme precision. The laser beam melts, burns, or vaporizes the metal as it moves along the programmed cutting path, resulting in clean, accurate cuts. This technology offers several advantages over traditional cutting methods.

One of the most significant benefits of laser cutting for sheet metal is its precision. Longtai Laser's machines can achieve extremely tight tolerances, often within ±0.1mm. This level of accuracy is crucial in industries such as electronics, aerospace, and automotive, where even the slightest deviation can lead to product failures. For example, in the production of electronic enclosures, precise laser - cut holes and edges ensure a perfect fit for components, enhancing the overall functionality and aesthetics of the product.

These machines can work with a wide range of sheet metals, including stainless steel, carbon steel, aluminum, and copper. Different thicknesses of sheets can also be processed, from thin foils to relatively thick plates. Longtai Laser's sheet metal laser cutting machines are equipped with advanced control systems that allow for easy adjustment of cutting parameters based on the type and thickness of the metal, ensuring optimal results for every job.

Laser cutting is a fast - paced process. Compared to mechanical cutting methods that may require multiple passes or complex tool changes, a laser cutting machine can complete cuts in a single pass, significantly reducing production time. Longtai Laser's high - power lasers enable rapid cutting speeds, increasing productivity without sacrificing quality. This efficiency is particularly valuable for high - volume production runs, helping manufacturers meet tight deadlines and increase their output.

Longtai Laser has a comprehensive range of sheet metal laser cutting machines designed to cater to different industrial requirements.

For heavy - duty applications and thick - gauge metal cutting, Longtai Laser offers high - power sheet metal laser cutting machines. These models are equipped with lasers that can deliver powers ranging from several kilowatts to tens of kilowatts. The high - power lasers can quickly penetrate and cut through thick stainless steel or carbon steel sheets, making them ideal for industries such as construction, shipbuilding, and heavy machinery manufacturing.

In addition to the high - power machines, Longtai Laser also provides compact and flexible sheet metal laser cutting solutions. These machines are suitable for small - to - medium - sized enterprises and workshops that may have limited floor space but still require high - quality cutting capabilities. The compact design does not compromise on performance, as these machines are equipped with advanced features such as automatic focus adjustment and high - speed motion control systems, allowing for efficient and precise cutting of various sheet metal projects.

Longtai Laser's automated sheet metal laser cutting systems are designed to streamline the production process. These systems can be integrated with material handling equipment, such as automatic sheet loaders and unloaders, to enable continuous operation. The automation not only reduces labor costs but also improves the consistency and quality of the cuts. With the ability to program complex cutting patterns and sequences, these automated systems are highly efficient for large - scale production of sheet metal components.

Longtai Laser incorporates state - of - the - art technology into its sheet metal laser cutting machines to ensure superior performance.

The company uses high - quality laser sources from leading manufacturers. These laser sources are known for their stability, high energy conversion efficiency, and long lifespan. The advanced laser technology allows for precise control of the laser beam's power, frequency, and pulse width, enabling optimal cutting performance for different types of sheet metals.

Longtai Laser's machines are equipped with high - precision motion control systems. These systems use advanced servo motors and linear guides to ensure smooth and accurate movement of the laser cutting head. The motion control system can achieve high - speed acceleration and deceleration, allowing for fast and precise cutting along complex paths. Additionally, the system is capable of compensating for any mechanical vibrations, ensuring consistent cut quality throughout the cutting process.

The machines are operated by intelligent control software that is user - friendly and highly customizable. The software allows operators to easily input cutting parameters, such as the type of material, thickness, and cutting speed. It also provides real - time monitoring of the cutting process, including the status of the laser source, the motion of the cutting head, and the quality of the cuts. In case of any issues, the software can issue alerts and provide troubleshooting guidance, minimizing downtime and ensuring continuous production.

Longtai Laser's sheet metal laser cutting machines find applications in a wide variety of industries.

In the automotive industry, these machines are used for cutting various sheet metal components, such as car body parts, chassis components, and engine brackets. The high precision of laser cutting ensures a perfect fit of these components, which is essential for the safety and performance of the vehicle. Laser - cut parts also have a better surface finish, reducing the need for additional finishing operations.

For the electronics industry, Longtai Laser's sheet metal laser cutting machines are used to cut components for electronic devices, such as enclosures, heat sinks, and circuit boards. The ability to cut intricate shapes and small holes with high precision is crucial in this industry, where miniaturization and high - density packaging are key trends.

In architecture and decoration, sheet metal laser cutting machines are used to create customized metal designs for facades, interior decorations, and furniture. The versatility of laser cutting allows for the creation of complex and unique patterns, adding a touch of elegance and individuality to architectural projects.

Even in the jewelry and art industry, Longtai Laser's machines play a role. They can be used to cut precious metals such as gold, silver, and platinum into intricate designs for jewelry making. In the art world, laser - cut metal sheets can be used to create sculptures and art installations, offering artists a new medium to express their creativity.

When it comes to investing in a sheet metal laser cutting machine, there are several reasons why Longtai Laser stands out.

Longtai Laser has a reputation for manufacturing high - quality and reliable laser equipment. The company adheres to strict quality control standards throughout the production process, from the sourcing of components to the final assembly and testing of the machines. This ensures that every sheet metal laser cutting machine leaving the factory is of the highest quality and can operate continuously and reliably for years.

Longtai Laser provides comprehensive technical support and after - sales service. The company has a team of experienced technicians who are available to assist customers with installation, training, and maintenance of the machines. In case of any technical issues, the support team can provide prompt solutions, either on - site or remotely. This ensures that customers can maximize the uptime of their machines and minimize production disruptions.

Understanding that different customers have different requirements, Longtai Laser offers customization options for its sheet metal laser cutting machines. Whether it's adjusting the machine's specifications to fit specific production needs or developing customized software features, the company can work with customers to provide tailored solutions.

In conclusion, Longtai Laser's sheet metal laser cutting machines offer a combination of precision, efficiency, and versatility that is hard to match. With advanced technology, a wide range of product offerings, and excellent customer support, Longtai Laser is the go - to choice for businesses looking to enhance their sheet metal cutting capabilities. Whether you are in the automotive, electronics, architecture, or any other industry that requires high - quality sheet metal cutting, Longtai Laser has the right solution for you.