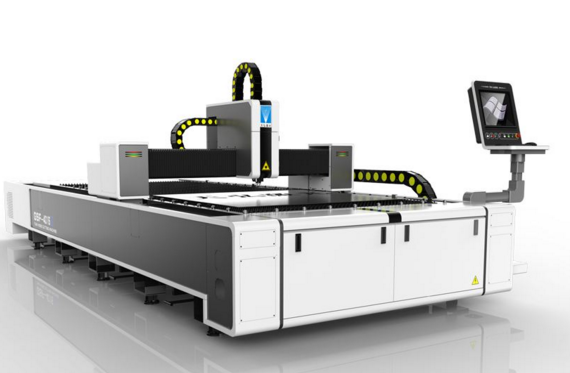

Fiber laser cutting machine and carbon dioxide cutting machine better.

Fiber laser cutting machine and carbon dioxide cutting machine, who is better? These two cutting machines are often used in industrial production, of course, these two cutting machines have their own advantages, but from the current use of the situation, many factories prefer to choose optical fiber cutting equipment, rather than carbon dioxide cutting equipment. Thus it can be seen that fiber cutting equipment is slightly better in performance than CO2 cutting equipment. Now let's talk about why more and more customers choose to use fiber optic cutting equipment.

Compared with carbon dioxide cutting machine, the first advantage of optical fiber laser cutting machine lies in the advantage of energy utilization. This kind of machine and equipment is transformed into the corresponding cutting kinetic energy by electricity, and the conversion rate of energy of optical fiber cutting equipment is higher theoretically. Using optical fiber cutting equipment is better than using it. Carbon dioxide cutting equipment can save more energy, the use of optical fiber cutting equipment can save about 10% of the energy for enterprises, making the production cost of enterprises to a certain extent reduced. In addition, from this aspect, it is obvious that the cutting effect of carbon dioxide cutting equipment is not as good as that of optical fiber cutting equipment. The surface of the things cut by optical fiber cutting equipment is very smooth and smooth, and the materials cut can be directly used without secondary processing. Carbon dioxide cutting equipment may have burrs or burrs when it is cut out, and there may be irregular problems when it is cut out. Then follow-up processing operation is needed, which will invisibly increase the complexity of processing and indirectly increase the cost of processing. From the maintenance point of view, the cost of maintenance of carbon dioxide cutting equipment will be higher, and the optical fiber cutting equipment basically does not need special maintenance. This kind of machine equipment is very precise instrument and equipment. In the process of use, only some wear-and-tear parts need to be replaced, and its cutting accuracy can be achieved. Guaranteed for a long time.

From the introduction above, we can know that although carbon dioxide cutting equipment has been used for a long time, but this new type of optical fiber laser cutting equipment has a stronger advantage, many manufacturers will not help. Optical fiber laser cutting is chosen independently, and the relatively backward carbon dioxide cutting mode is gradually eliminated.